Bespoke

High Quality Bespoke Industrial Material Handling Equipment

– An Electric Lifter That Fits Your Exact Need

Granting our customers their wishes, and building the exact custom industrial material handling lifter they desire, is what we enjoy. We know of nothing better.

As engineers we also love solving technical challenges and implementing innovative growth. But again, as humans, very few things are as rewarding as a happy customer getting that material handling lift designed to meet their special challenges.

However, in the beginning, before reaching this satisfactory goal, as a customer there are often important pros and cons to weigh against each other. Maybe you recognize some of the following considerations :

- Bespoke lift equipment is often very expensive

- A custom electric lifter often takes a long time to design

- Because of its unique, never-built-before quality, it might not yet be a fully reliable piece of handling machinery

We fully understand those reservations. They are a good reflection of a very common reality. But we are also happy to inform you that here at 2Lift, we have a history of proving the opposite.

Thanks to the innovative 2Lift Modular Design, we can say that our custom material handling lift equipment is now both affordable, fairly quick to produce and is of strong, reliable, and durable quality.

Let’s take a quick look at what is so special about bespoke electric lifters from 2Lift.

Custom Industrial Material Handling Equipment from 2Lift Fuses Reliable Modular Design with Solution Orientated Innovation

In our opinion combining existing knowledge with new ideas always makes for the best solutions.

In the same manner, building the basic structure of bespoke industrial material handling solutions from well-tested modular components, paves the way for a reliable and very solid piece of equipment.

And because they are modular components, the flexibility in end-solution is almost never-ending.

In metaphorical terms, you can compare our shelves filled with modular components to a huge Lego-filled box with bricks in all the shapes, sizes, and colours imaginable.

In this way, modular design allows us to combine our components in pretty much which ever way we please, which means that you get a bounty of opportunities for getting your lifter built in the exact way you desire.

The only thing left after the application of modular design is fine-tuning and customisation, which is now easy and highly manageable (compared to the scenario of having to customise every single component from scratch).

This means that when you order a custom industrial material handling solution with us, you get the benefits of both:

– Well-tested, reliable and affordable standardisation as the solid foundation.

– Unique, innovative, specially-built customisation that takes it all one step further.

So, What Is Your Challenge?

There may be several different reasons as to why you think you need bespoke industrial material handling equipment. In our experience the reasons typically fall into one of the following categories.

Maybe you have:

– Loads that are odd-shaped or have non-standard geometry

– Lifting and / or handling requirements that are unusual or demanding

– Work area challenges in terms of e.g. constricted physical work environment layout

We solve such challenges by working on one or both of the following parameters:

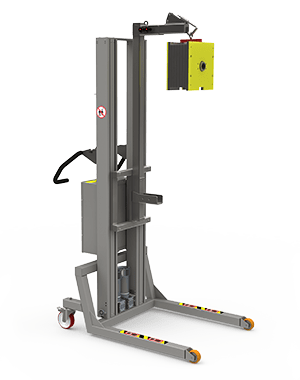

- We adjust the lifter’s dimensions and recommend the most appropriate steel alloy.

- We custom build the lifter tool (also called end-effector) to a perfect fit for your lifting and handling requirements.

Adjusting the Lifter’s Dimensions and Choosing the Optimal Material

If for some reason, your working environment constitutes a challenge, we can easily adjust our industrial material handling equipment to fit in nearly anywhere.

Maybe you have:

– Narrow hallways or aisles

– Challenging and tight corners

– Low door frames

– Space-constricting machinery

– Strict industry regulations

If so, we can easily adjust the dimensions of our electric lifters by e.g. shortening or lengthening the lifter’s height or its protruding legs without reducing safety or comfort. For instance if you need the legs to be shorter, we will stabilize the lifter by adding sufficient counter weight at the back of the legs.

If you work in a clean room environment and need to abide by GMP, all our steel lifters also come in a stainless steel version (AISI 304 and AISI 316L).

In most cases, we don’t consider minor adjustment of the lifter’s dimensions or choice of material as customisation, we consider it an option.

Customising the Lifter Tools

At 2Lift, adjusting the lifter tools to the perfect fit is where real customization comes into the picture.

In order for us to help you the best we can, it is now time to consider if you need to only LIFT something or both LIFT AND HANDLE (e.g. tip, turn, or rotate) the load?

– If you need to only lift something, be it a variation of rolls / reels , drums, vessels, pallets, boxes, containers or something completely different, then you might find inspiration in our Custom Non-Manipulators Gallery, which you’ll find right below this section.

– If you need to both lift and handle something, then please scroll down this page until you reach our Bespoke Manipulator Gallery.

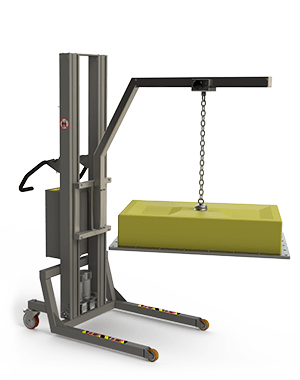

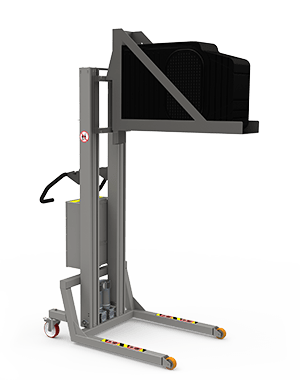

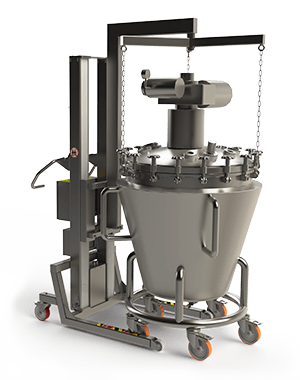

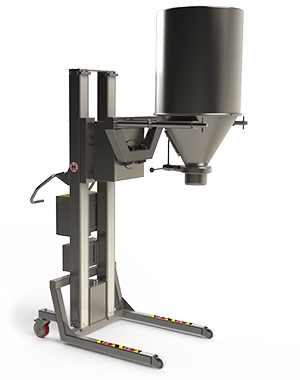

Custom Non-Manipulators Gallery

– Lifting Tools Inspiration

In this gallery it is our intention to present good examples of various custom industrial material handling equipment that we’ve built for our customers during the years.

Such solutions are what you’ll be looking for if your needs are to grab, lift a load up and down, and then release it.

We can custom build platforms, forks, booms, double booms and mandrels to suit your load perfectly.

Crane Lift with Adjustable Boom Arm

Crane Lifter with Boom Arm for Machine Cover

Lifting Apparatus with Special Platform for Vessels

Smart Handling System with Special Tool for Extruder Unit

Special Lifter Tool for Handling Cassettes

Specialist Lifting Equipment for Lifting Mixer Lid

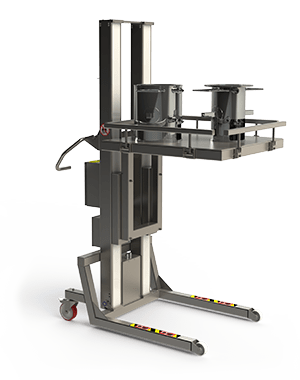

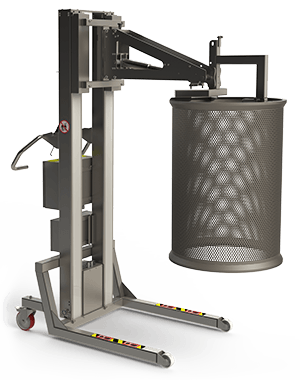

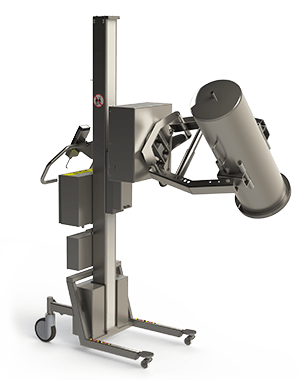

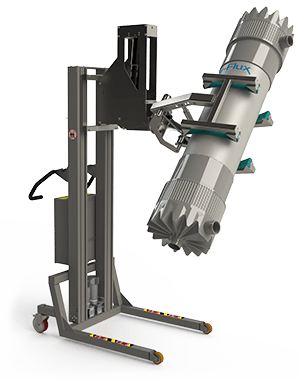

Custom Manipulators Gallery

– Lifting and Handling Tools Inspiration

In this gallery you’ll find a variety of different bespoke industrial material handling solutions that are characterized by lifting tools that can both lift AND handle various loads.

Such solutions are what you need if your requirements go beyond merely lifting up and down but also include a need to e.g. rotate, tip, turn or empty a load.

We can easily custom build our lifter tools such as linear clamps and scissor clamps.

Clean Room Equipment: Lifting Solution with Rotating Double Mandrel for Vessel

Cleanroom Lifting System for Tipping a Filter

Industrial handling machine to grip and hold boxes

Lift Clamp for Handling Filter Housing

Lifting Clamp for Manipulating Large Filter

Lifting Mechanism for Gripping Cans

Our In-Depth Dialogue Method Ensures That Nothing Is Left to Chance

How do we make sure that we’ve understood everything in depth and breadth?

Well, besides being guided by our checklist with standard questions, we simply continue to ask and ask until we feel confident that no stone is left unturned regarding your lifting and handling situation.

As a starting point in our dialogue, we will typically ask you the following questions:

What is it you need to lift and or handle? Reels / rolls, drums, barrels, vessels, pallets, skids, boxes, containers, or something else?

What is it you need to lift and or handle? Reels / rolls, drums, barrels, vessels, pallets, skids, boxes, containers, or something else?- For determining the overall type of lifter tool.

- What are the load’s dimensions? Height, width, circumference, diameter etc.

- For estimating potential customization of the lifter tool.

- What type of operation is your load to perform? Does it need to only lift, or does it also need to handle the load in any particular manner?

- For concluding whether you need a manipulator or non-manipulator variant.

- How heavy is your load?

- For determining whether you need a 150 kilo lifter or a 300 kilo lifter.

- What characterizes your working environment? Are there any potential constrictions?

- For assessing the optimal dimensions of the lifter and whether adjustment of e.g. height or legs is required.

- What is your industry e.g. pharma, food and beverage, storage or something else? Are there any important industry regulations to comply with e.g. GMP?

- For determining whether you need a steel lifter or stainless steel lifter.

If you think that we may help you build the perfect industrial material handling lifter for your working environment, please don’t hesitate to contact us. Our engineers are ready by the phones to answer any questions you may have. We look very much forward to hearing from you.

Go to our Homepage.

What is it you need to

What is it you need to