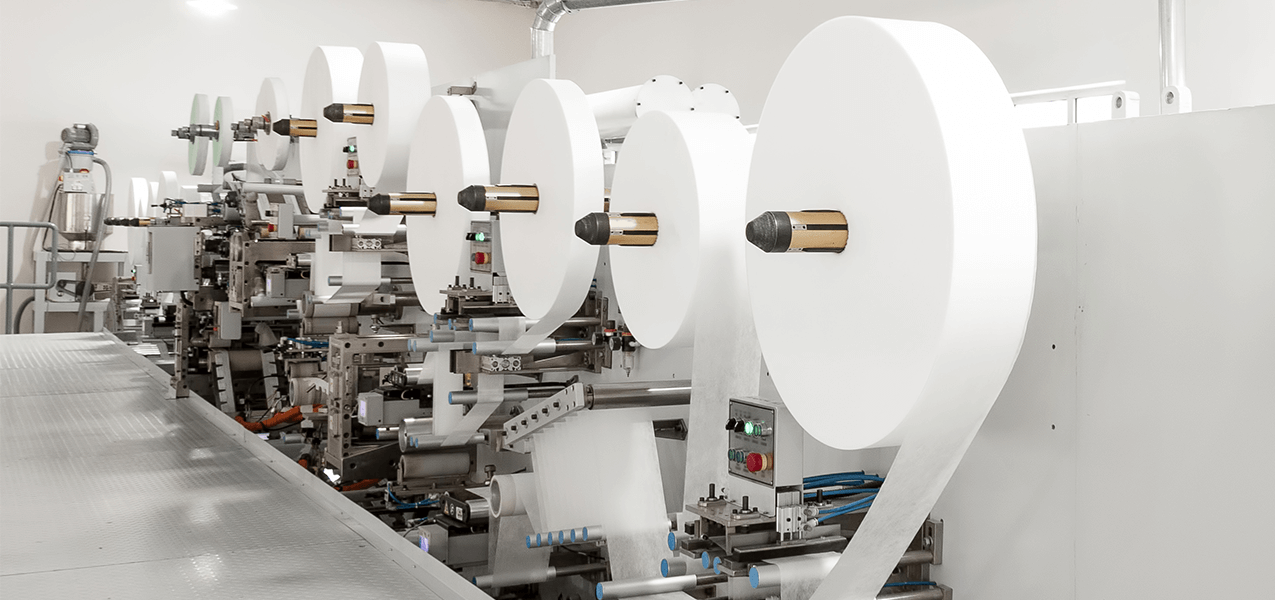

Handling Rolls

Innovative Roll Lifting Equipment for Standard Reel Lifting and Complex Roll Handling

At 2Lift we welcome all needs for roll lifting equipment – be that needs for standard reel lifting or more complex roll handling.

Industrial roll handling and lifting is one of our primary specialties and our customers’ needs for reel lifters are as varied as the industries from which they come – and we are very happy to meet them all.

We encounter all sorts of reel lifter needs:

- Right from the standard reel lifting and transporting operation in not so highly regulated, spacious environments …

- To the more complex roll handling operations …

- for potentially fragile, and odd shaped rolls, reels, and spools

- in industries with highly regulated work environment procedures (in e.g. cleanrooms)

- in working areas with limited and restricted access for gripping, transporting and docking

- where the need to tip, turn and rotate the roll in a particular manner may be required.

We Serve a Broad Palette of Industries

We are proud to have delivered countless standard and customized reel lifting and roll handling solutions to many different branches both within the converting industry as well as other fields of production and manufacturing:

- Pulp and Paper

- Textile

- Packaging

- Pharmaceutical / Medical

- Food and Beverage

- Manufacturing

Struggling with Your Heavy, Delicate Rolls or Odd Shaped Reels? We Can Handle Them!

The innovative technology behind our material handling lift solutions allows us design, adapt, and build a strong and reliable roll handling lifter for any type of roll you may present us with.

We have handled all shapes, sizes, surfaces and contents of rolls within the weight limit of 500 kg (including the weight of the lifter tool).

Here is a non-exhaustive list of roll types for which we have designed roll lifting equipment:

- Film

- Aluminum Foil

- Paper

- Textile

- Non-wovens

- Plastic

- Rubber

We Think Your Lifting Task Through From Beginning to End

– We Thoroughly Analyze Your Roll Handling Needs Before Building Your Roll Lifting Equipment

At 2Lift we have years of experience in the handling of all manner of reels / rolls / spools and understand the many factors involved. For every lift we sell, we think the lifting task through from beginning to end.

Because there may be so many important elements to consider when choosing your roll lifting equipment, we have developed an efficient (leaving-out-nothing) dialogue based procedure.

This procedure guarantees that all your needs and requirements will be addressed and built into the design of your reel lifter.

Areas we will assess and analyze before building and adapting / designing your roll lifting equipment are, among other things:

- The official work environment standards, requirements, and regulations that pertain to your industry.

- The physical characteristics of the work area / space.

- The reel / roll dimensions (size, weight, and core diameter) and the roll material (both surface and content).

- Roll handling needs in terms of e.g. transport and potential tipping, turning, rotating, docking etc.

All these thorough measurements are taken to:

- Guarantee your employees’ physical safety in terms of preventing injuries and maintain their level of ergonomic health.

- Optimize your company’s work flow processes and efficiency.

- Ensure that your products remain undamaged and intact (that coil of the rolls is not compromised during the gripping / roll handling process, and that the surface and content of the rolls are optimally protected during clamping, transport, and docking).

Discover Our Innovative and Flexible Roll Lifting Equipment Solutions

The extensive variety of needs in roll lifting equipment is well reflected in our many different end-effectors and lifter solutions for reel / roll handling.

We always do our very best to take all possible regulative, environmental, and physical factors into account in when designing and adapting our roll lifters.

We will consider, among other things:

We will consider, among other things:

- Wind-off orientation.

- Risk of rolls telescoping (to prevent such incidents we have developed several anti-telescoping attachments that will stabilize the roll before rotating, tipping, and end placement).

- Potential damage to the core or surface of the reels during the lifting process, and much, much more.

Based on these many considerations, we always strive to offer the best possible roll lifting solutions to our customers.

If our standard reel handling solutions do not solve a given lifting task, our lifters are designed to be extremely flexible. All our material lifters are born with the strength of the 2Lift Modular Design, providing you with endless possibilities of receiving innovative and reliable custom solutions to solve problems that no standard lifter could.

To provide you with an impression of what we can do for you, here is a non-exhaustive presentation of our fully flexible and adaptive friendly roll lifting equipment.

All roll lifting solutions come in steel and stainless steel and may lift up to 500 kg (including lifter tool):

Roll Handling Lifts with Core Grippers

There may be several reasons why lifting rolls with a core gripper might be the ideal end-effector solution for your needs.

Reasons for deciding on end-effectors with a core gripper:

- If you have delicate, pressure-sensitive rolls where the material and / or surface needs to remain untouched.

- If the position of the rolls make it difficult to grab them on the outside, for instance when they are stacked closely during storage.

Model ERM: Electric Roll Manipulator

With this fully electric roll lifter solution, the rolls are gripped in the core with an electrically activated expanding mandrel. The reel core is gently fastened to the mandrel via a tooth plate.

When securely fastened, reels can then be tipped up or down, from core horizontal to core vertical.

This is the ideal solution for non-through-shaft applications, for instance when reels need to be lifted and tipped from a pallet and placed on a fixed mandrel.

Our electric roll manipulator can lift up to 350 kg.

Model MRM: Manual Roll Manipulator

This manual version of the roll handling lift above offers a cost effective alternative, ideal for lifting and turning lighter rolls. While the the gripping and turning of the roll is manual, the lifting and lowering functions are still electrical.

The lifting principles are the same as with the Electric Reel Manipulator allowing reels to be gripped in the core and then lifted/tipped up and down. The way of gripping the core is also similar but is activated by the use of a handle. Up to 400kg.

Model RM: Mandrel with Rollers

For simple roll lifting, a good and cost effective solutions is a mandrel.

To ease the movement of the roll on the mandrel, this can be fitted with rollers; in addition a brake is also mounted to ensure that the reel does not roll off the mandrel unintentionally.

This solution is particularly good for moving rolls with the core horizontally where tipping or turning is not required. Up to 450kg.

Roll Lifting Equipment with External Roll Handling

An external roll handling application may be the preferred choice if e.g.:

- The roll core needs to stay open (perhaps for docking purposes)

- The core is of more fragile material (e.g. thin plastic or cardboard)

- The roll needs a through-the-core shaft.

Model VB: Roll Lifter with Boom and V-Block

For external handling of rolls (non-core gripping solutions) a simple and effective solution is a boom V-block tool.

With this, rolls can be rolled or tipped onto the V-block from a pallet and then lifted.

Since the V-block can rotate, the orientation of the roll core can be positioned to accommodate mounting the roll where necessary.

This solution also supports through-shaft applications as the roll core is easily accessible while the roll is on the V-block.

The V-block can easily be removed allowing the boom holding it to be used to lift rolls as well. Up to 400kg.

Model DM: Roll Handling Lifter with Double Mandrel

For external handling of heavy rolls (non-core gripping solutions) a simple and effective solution is a double mandrel lifter tool.

Using the double mandrel, reels standing with the core in the horizontal position can be lifted directly of the floor or a pallet and placed on a mandrel. This solution is best for non-through-shaft applications, since the reel cannot be rotated after lifting.

For reels with different diameters an adjustable double mandrel is used allowing the distance between the mandrels to accommodate a large range of reel diameters. Up to 430kg.

Model ERU-EC: Roll Handling with Electric Scissor Clamp and Rotation Unit

For through-shaft applications where electrical gripping and turning are needed, the clamp and rotation unit are ideal. Up to 120kg.

Gripping the reel on the outside diameter using grippers lined with soft rubber, the reel can be lifted and turned to core-horizontal position, where after the shaft can be placed in the core of the reel.

Finally, using the roll lifter, the reel and shaft can be placed where needed.

Model FN: Roll Lifting Fork with Notches

For through-shaft applications a simple fork with notches can be applied to lift reels after the shaft has been placed through the core.

Plastic supports in the notches protect the shaft from damage during roll handling and the dimensions of the lifting tool can easily be customized to fit specific reels and shafts. Up to 450kg.

Model ERG: Electric Reel Lifter – a Manipulator with External Gripper

With this reel handling solution, the reel is gripped on its outer edge with an electrically activated clamp. Once clamped, the reel can then be tipped to a position where the core is horizontal. Up to 350kg.

The gripper on the ERG can be modified to fit a wide range of reel sizes.

Safety, Comfort and Ergonomics

At 2Lift it is quintessential that we can be trusted to ensure both optimal product protection as well as human safety and health. Thus considerations for safety, comfort and ergonomics are weaved in at all levels of the lift building and usage process, right from our design considerations, to testing, and shipping to end-user application.

- Our roll lifting equipment is designed to increase work flow efficiency while at the same time prevent work injuries and sustain optimal human ergonomic health. The human force limits for push and pull factors are carefully analyzed and built into the lifter design, so that manual mechanical usage will never put damaging strain on the body.

- Every single roll handling lift and its components are submitted to thorough in-house testing and documentation before it leaves our facilities.

- All roll lifting equipment is safely wrapped and packaged before shipping and will arrive at your facility all ready-to-use, with no assembly needed.

Not Finding Exactly What You Need Here?

– No Worries, We Are Experienced Specialists in Customized Roll Handling Solutions

With customers in more than 20 countries worldwide, we know fully well that needs, requirements, and regulations for roll lifting equipment vary greatly.

Not only will we help you find the best material handling lift for your specific needs and budget (we also design and build reliable, high quality drum handler solutions, specialized pallet lifters and industrial material lifting equipment for boxes, we are also very happy to adapt our current lifters to suit your unique needs and even custom design from scratch if required to create the perfect fit.

For inspiration, we invite you to take a look at our custom solution section. If you need help or have any questions, please don’t hesitate to contact us.

Handling Other Loads

Handling Drums

Discover our ergonomic drum handler solutions in steel or stainless steel for lifting and handling almost any type of drum or barrel. In our drum lift gallery you can find examples of drum handler equipment for sideways rotation or forward tipping.

Handling Pallets

Get an overview of our innovative, flexible, and customized pallet lifter solutions in steel and stainless steel. Here you’ll find illustrative examples of bespoke electric pallet stacker equipment that go beyond the ordinary pallet jack.

Handling Boxes

Explore our wide selection of industrial material lifting equipment for lifting and handling all sizes, types, and materials of boxes. Our flexible, reliable, and industry regulated box handling machinery is available in both steel and stainless steel.

Go to our Handling page for an overview of how we handle different kinds of loads.

Go to our Homepage.