Options for Lifters

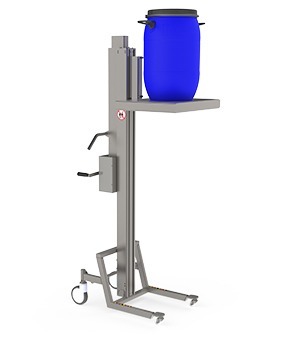

Customise Your Lifting Equipment: Options for Lifters

Our lifting equipment come with a range of options that help to make them more suited for different environments or specific work situations.

Choose from the the options below to customise your lifter to fit your specific requirements.

Alternative RAL Colour

Our non-stainless lifters (N line) can be supplied in alternative RAL colors in addition to the standard colour.

ATEX

For use in environments with explosive atmospheres (EX-zone), we offer lifters that are compliant with the ATEX-directive.

Docking System

There are situations where it is critical that the lifter is positioned at a precise location. In cases like this, we offer a docking system that allows for quick and easy positioning of the lifter.

EN 1.4404 – AISI 316L

For use in extremely corrosive environments, we can deliver our stainless lifters in AISI 316L / EN 1.4404.

ESD – Electrostatic Discharge

For use in environments were the build-up of static electricity is prohibited, we offer lifters that are compliant with the electrostatic discharge standard.

Exchangeable Battery

The exchangeable battery system ensures that the lifter is always charged and ready to go.

PPS – Programmable Position Stop

The programmable position stop system (PPS) allows the user to pre-select 10 height positions, which can then easily be recalled allowing the lifter to stop precisely at the desired height.

RTC – Rapid Tool Change

The rapid tool change adaptor (RTC) allows the same lifter to use multiple lifting tools and makes exchanging these easy and time efficient.

Our Options’ Compatibility with Our Lifter Lines

For a quick way to find out whether your desired option is compatible with the type of lifter you need, please take a look at the table below.

| ATEX | Docking | 316L | ESD | Exch. Battery | PPS | RTC | RAL | |

|---|---|---|---|---|---|---|---|---|

| C-Line – see here Economic, lightweight, steel |

X | X | X | |||||

| N-Line – see here Strong, versatile, steel |

X | X | X | X | X | |||

| SN-Line – see here Strong, versatile, stainless steel |

X | X | X | X | X | X | X | |

| SF-Line – see here Food and beverage, hygienic, stainless steel |

X | X | X | X | X | X | X | |

| SP-Line – see here Pharma, GMP, stainless steel |

X | X | X | X | X | X | X |

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.