SP-Line

SP-Line Electric Lift Solutions Tailored to the Pharmaceutical and Biotech Industry

Our SP-line of electric lift solutions is tailored to the pharmaceutical and biotech industry with focus on compliance to industry standards.

Custom solutions and a wide range of options are also available to suit almost any need.

Our Versions of SP-Line Electric Lift Solutions

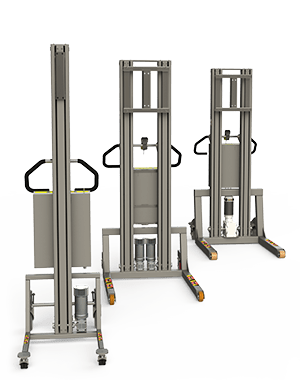

The SP-line of electric lifters delivers three different load lifting classes, the SP-150, SP-300 and SP-500. These are capable of lifting 150 kg, 300 kg and 500 kg (including the lifting tool), respectively.

SP-150

SP-300

SP-500

Lifting Production Equipment in Cleanrooms

Ideal for use in cleanrooms, these hygienic, electric lifting aids in stainless steel are used for a wide variety of lifting tasks, including lifting and rotating all manner of rolls, drums, barrels, sacks, cans, containers, vessels, filters, filter houses, boxes, trays, lids, covers, wash racks for washing machines etc.

Matching ISO Classes and Complying with GMP Regulations

We know that the hygienic and sanitary requirements of one type of cleanroom may differ widely from that of another. And we also understand how crucial compliance to cleanliness is in pharmaceutical production.

So it doesn’t matter whether your ISO classification is an ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8 or ISO 9, our design will be suited to match which ever class is needed. All worries about cross-contamination risks and stray airborne particles can be put to rest.

To further guarantee product safety, purity and quality in manufacturing processes we strictly adhere to the GMP (Good Manufacturing Practices) regulations issued and enforced by your country’s authorities and government agencies.

How Our Electric Lift Design Ensures Product Safety

As such, ease of cleaning and hygienic design has been a top priority throughout the design of our SP-series of material handling equipment.

Corrosive Resistant Stainlesss Steel: AISI 304 (1.4401) and AISI 316L (1.4301)

We offer to build our lifting machinery in two types of austenitic stainless steel, AISI 304 (1.4401) and AISI 316L (1.4301) all depending on the corrosion resistance required. The chemical composition of these two types of stainless steel are very similar except for the amount of molybdenum which is higher in AISI 316L which it more corrosive resistant and thus a safer choice in e.g. chloride rich environments. So if your environment is either acidic or salty or characterised by high temperature, AISI 316L is the way to go.

Water Resistance: Ingress Protection of IP65

All our mini lifts are rated with an ingress protection of IP65. This ensures that all electrical compartments are dust and water resistant and can withstand a jet of water which is relevant when needing to hose down the lifter. Also our material handling lifts are resistant to caustic cleaners and are as such are suitable for pharmaceutical cleaning practices.

Low Surface Roughness

Stainless steel should be easy to clean without the risk of microorganisms, dirt and bacteria adhering to the surface. The smoother the surface, the longer it will last (in terms of wear and tear) and the more hygienic it will be. Thus in a cleanroom environment it is crucial to strive for as low a surface roughness as possible. Our clean room equipment has a very low surface roughness of less than 1.6 Ra. In cases of product contact we can guarantee an even lower surface roughness of just 0.8 Ra.

Other Important Design Features Tailored to the Pharmaceutical Industry

To further avoid compromising hygiene we have designed a contamination free cam belt solution which constitutes the lifting mechanics inside the column of the lifter. Compared to the typical ball screw drive, this solution does not require any lubricants. It is in fact, maintenance free.

When choosing which wheels to use we take floor type into account in order to avoid as much friction as possible and of course making sure that no markings will be left on the floor.

Special SP-Line Lifter Options to Match Work Environments and Work Situations

To optimally match usage and environment we have designed some customising options. For use in cleanrooms we can offer nearly our entire palette of options except for alternative RAL colour as it is only available for our non-stainless steel lifters.

Otherwise can offer ATEX compliant lifters, docking systems, stainless steel for extremely corrosive environments (as already mentioned), ESD safe lifters, exchangeable batteries, a programmable position stop system and a rapid tool change adaptor.

ATEX

For use in environments with explosive atmospheres (EX-zone), we offer lifters that are compliant with the ATEX-directive.

Docking System

There are situations where it is critical that the lifter is positioned at a precise location. In cases like this, we offer a docking system that allows for quick and easy positioning of the lifter.

EN 1.4404 – AISI 316L

For use in extremely corrosive environments, we can deliver our stainless lifters in AISI 316L / EN 1.4404.

ESD – Electrostatic Discharge

For use in environments were the build-up of static electricity is prohibited, we offer lifters that are compliant with the electrostatic discharge standard.

Exchangeable Battery

The exchangeable battery system ensures that the lifter is always charged and ready to go.

PPS – Programmable Position Stop

The programmable position stop system (PPS) allows the user to pre-select 10 height positions, which can then easily be recalled allowing the lifter to stop precisely at the desired height.

RTC – Rapid Tool Change

The rapid tool change adaptor (RTC) allows the same lifter to use multiple lifting tools and makes exchanging these easy and time efficient.

Our Other Lines of Electric Lift Solutions

C-Line

N-Line

SF-Line

SN-Line

Go to our Lifters page for a more detailed overview of our lifter lines.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.