SP-300

SP-300:

Medium Sized Electric, Cleanroom Mini Lift Solutions for the Pharma and Biotech Industry

The SP-300 is the medium sized mini lift in the SP-line.

Designed for prolonged daily use in clean room environments, this vertical lifter is capable of lifting up to 300 kg (including the mounted lifting tool) and able to utilise all of our lifting tools, both simple, manual and electric.

The twin lifting column design on the SP-300 delivers added stability, making it the perfect choice for applications requiring high reach and/or loads placed far in front of the lifting columns.

Features

- Self-locking gear system for safety and accuracy. In case of electrical failure the mechanical system automatically brings the lifter to an immediate standstill.

- Large battery capacity with charge-state indicator. The large battery capacity allows for prolonged use of the lifter, even with the addition of electrical lifting tools.

- Easily customizable: height of lifting column and dimensions of wheel base can be modified to customer specifications.

- Rugged construction for industrial use. With its all-stainless steel construction, the SP-300 is built to last and for use in demanding industrial environments. Featuring a fully welded wheel base, these lifters do not become loose or wobbly even after many years of intensive use.

- Ergonomic handle designed to allow the user multiple different grips depending preference and situation.

- Robust remote control specifically designed for our lifters. Where practically all other lifters use a remote control with a plastic housing, our remote control features a full metal body and a high quality PU spiral cable. These remote controls do no crack or break when dropped and the cable remains flexible even after many years of use.

- Dual speed lifting and lowering. The control unit and remote control allow for either full speed operation or lifting at a reduced speed. The reduced speed is pre-set to the desired value on the control unit.

- Large range of lifting tools: both electrical and non-electrical lifting tools are available.

- Cambelt drive: The use of an AT-10 cambelt ensures smooth, reliable operation with no need for lubricants or continuous maintenance.

- Wheels and castors: We use non-marking wheels and swivel castors with quality bearings making the lifter easy to maneuver. A large selection of different wheels are available to ensure that they suit different height requirements and floor surfaces.

- Electronic overload protection – immediately stops all movement if lifter is overloaded.

SP-300 Mini Lift: Product Data

| SP-300L | SP-300M | SP-300H | SP-300HSP | |

|---|---|---|---|---|

| Lifting Capacity | 300 kg | 300 kg | 300 kg | 300 kg |

| Total Height | 1499 mm | 1984 mm | 2360 mm | 1310-3500 mm |

| Footprint (LxW) | 1252×780 mm | 1252×780 mm | 1252×780 mm | 1252×780 mm |

| Stroke | 895 mm | 1380 mm | 1756 mm | 696-2896 mm |

| Lifting Speed – No load | 130 mm/s | 130 mm/s | 130 mm/s | 130 mm/s |

| IP-rating | 65 | 65 | 65 | 65 |

| Rear Wheels | ø125 mm – Brake | ø125 mm – Brake | ø125 mm – Brake | ø125 mm – Brake |

| Front Wheels | ø80 mm | ø80 mm | ø80 mm | ø80 mm |

| Material | AISI 304 – Glass bead blasted | AISI 304 – Glass bead blasted | AISI 304 – Glass bead blasted | AISI 304 – Glass bead blasted |

| Battery Capacity | 24V – 18Ah | 24V – 18Ah | 24V – 18Ah | 24V – 18Ah |

| Battery Charger | Built in – 24V 3.5A | Built in – 24V 3.5A | Built in – 24V 3.5A | Built in – 24V 3.5A |

| Power Supply | 115-230V AC | 115-230V AC | 115-230V AC | 115-230V AC |

| Control Unit | Solid-state PLC | Solid-state PLC | Solid-state PLC | Solid-state PLC |

| User Control System | Remote control with E-stop for manipulators | Remote control with E-stop for manipulators | Remote control with E-stop for manipulators | Remote control with E-stop for manipulators |

| Overload Protection | Current monitor with cut-off | Current monitor with cut-off | Current monitor with cut-off | Current monitor with cut-off |

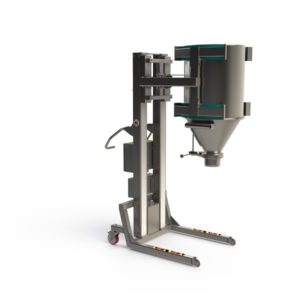

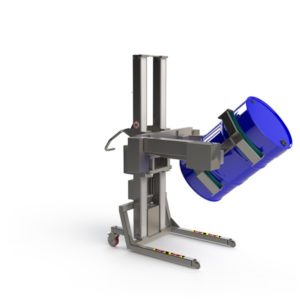

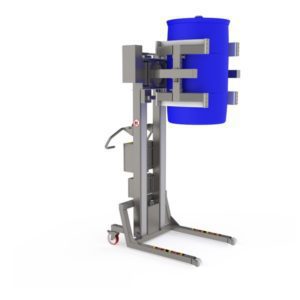

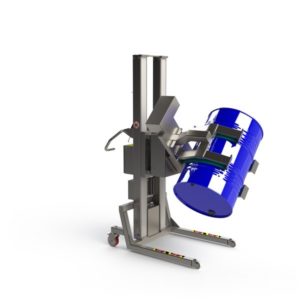

Examples of SP-300 with lifting tools

For lifters with other load capacities on the SP-Line, see our SP-150 page or SP-500 page.

Go to our SP-Line page for more general information on this line.

Go to our Lifters page for a more detailed overview of our lifter lines.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.