Electrical Manipulators

Industrial Lifting Equipment: Electrical Manipulators

Electrical manipulators are types of lift equipment that in themselves can be turned, swung or otherwise moved electrically to help position the load. This is an advantage over manual manipulators when the user does not have easy access to the lifting tool when the load must be manipulated, e.g. lifting to a height where access is restricted.

Also electrical manipulators can offer faster speeds than manual manipulators and handle heavier loads.

In cases where a tactile sense of the load is needed during positioning or for more cost efficient solutions, see our manual manipulators here.

For an overview of our electrical manipulators, see below:

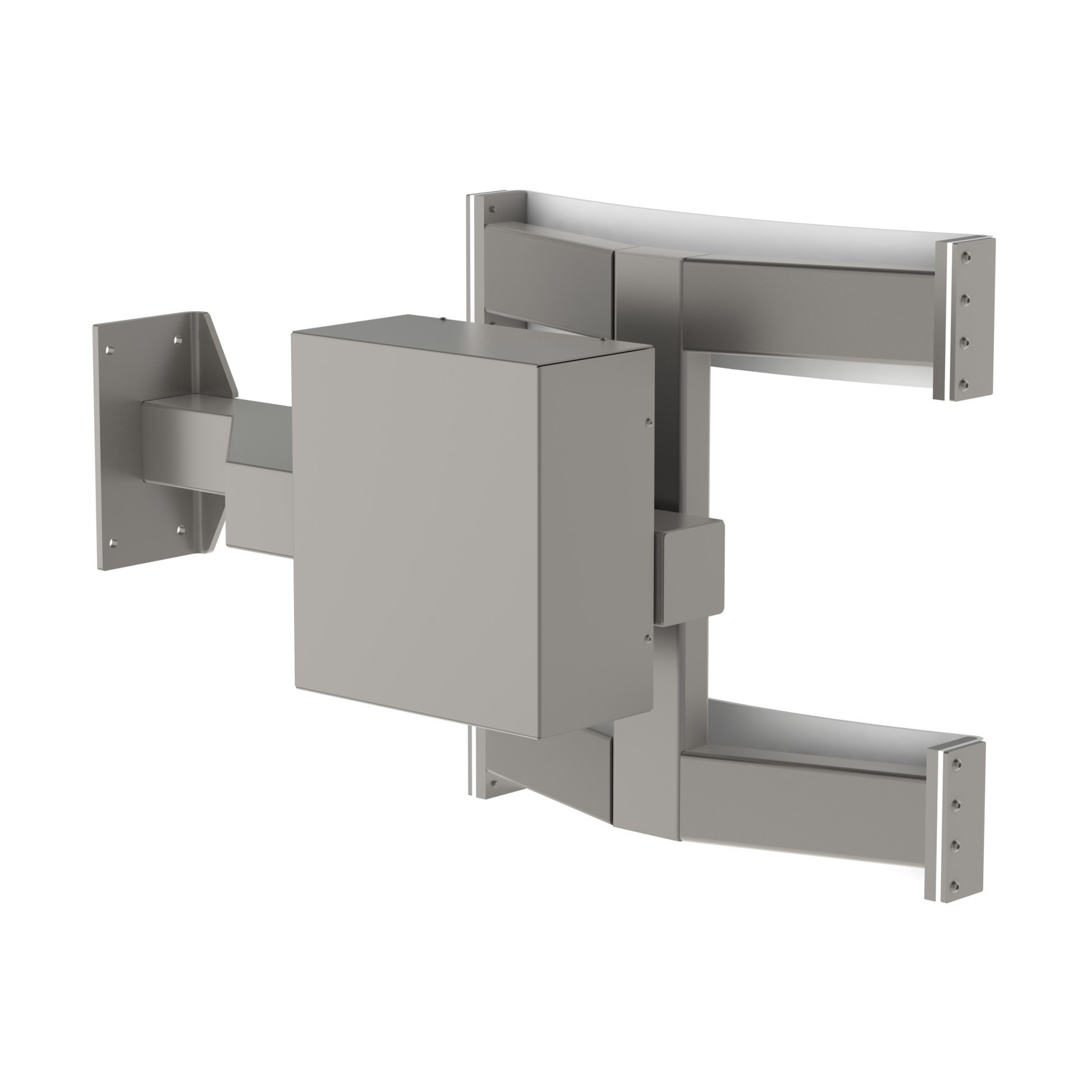

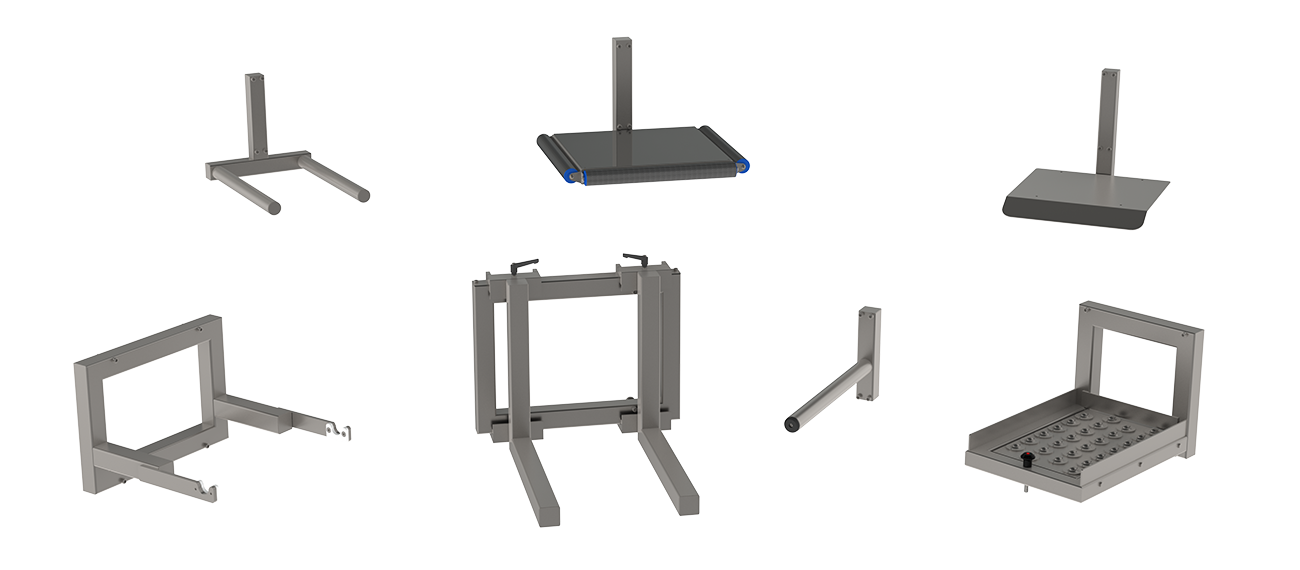

EC – Electric Clamp

EEU – Electric Expander Unit

ELC – Electric Linear Clamp

ELU – Electric Leveling Unit

ERG – Electric Reel Gripper

ERM – Electric Roll Manipulator

ERU – Electric Rotation Unit

ETU – Electric Tipping Unit

Other Tools Categories

Manual Manipulators

Manual manipulators are lifting tools that in themselves can be turned, swung or otherwise moved by hand to help position the load.

Non-Manipulators

Non-manipulators are simple lifting tools that support a load. Typically designed to accommodate a specific type of load, these tools are found in countless different versions.

Go to our main Tools page for an overview of the different categories of tools that we offer.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.