Non-Manipulators

Industrial Lifting Devices: Simple Non-Manipulators

Non-manipulators are simple lifting devices that support a load. Typically designed to accommodate a specific type of load, these lifter tools are found in countless different versions.

In cases where the load needs to be manipulated beyond being lifted up and down, see our manual and electrical manipulators.

For an overview of our non-manipulator lifting tools, see below:

AF – Adjustable Fork

CA – Crane Arm

DM – Double Mandrel

F – Fork

FN – Fork with Notches

M – Mandrel

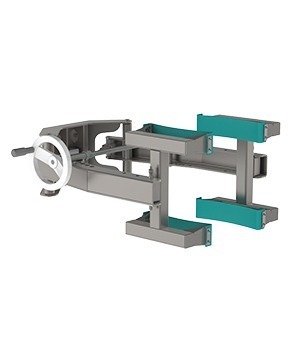

MC – Manual Clamp

MCS – Manual Clamp with Spindle

MLC – Manual Linear Clamp

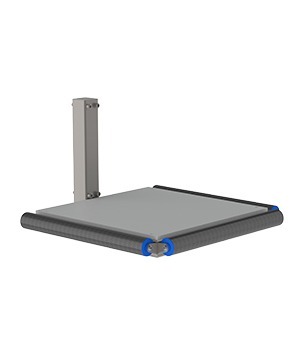

MP – Metal Platform

MPR – Metal Platform with Rollers

PP – Plastic Platform

PPR – Plastic Platform with Rollers

RM – Roller Mandrel

RP – Roller Platform

Other Tools Categories

Electrical Manipulators

Electrical manipulators are lifting tools that in themselves can be turned, swung or otherwise moved electrically to help position the load.

Manual Manipulators

Manual manipulators are lifting tools that in themselves can be turned, swung or otherwise moved by hand to help position the load.

Go to our main Tools page for an overview of the different categories of tools that we offer.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.