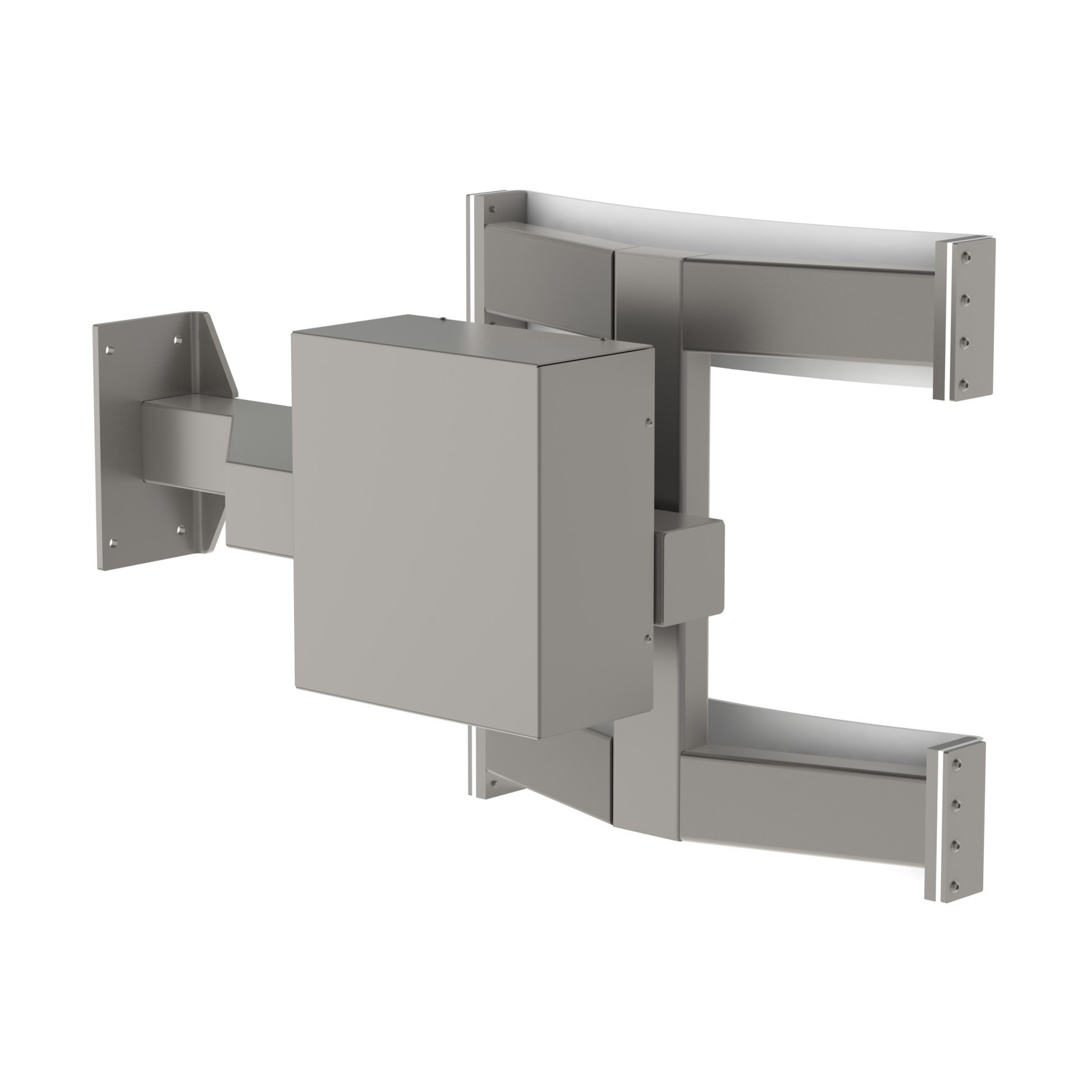

ERM – Electric Roll Manipulator

ERM – Electric Roll Manipulator:

Powerful Roll Handling Tool for Heavy Lifting and Turning

This fully electrically powered version of our roll handling equipment offers a perfect solution for lifting and turning heavy rolls.

Also, since the gripping is electrically powered, this is an ideal solution where there is not space for the operator to stand next to the roll while gripping is performed. The lifting principle allows rolls to be gripped in the core and then tipped. The gripping of the core is achieved with an expanding mandrel that is activated by an electrical actuator.

Exchangeable grippers allow the ERM to grip different cores sized from ø76 mm and up.

The motion is easily controlled using the remote control on the lifter.

Features

- Can be adapted to fit multiple core sizes.

- Fully electrically powered, both gripping and tipping.

- Rugged construction for industrial use. With its all-stainless steel construction, the ERM is built to last and for use in demanding industrial environments.

- Available in hygienic design for use in cleanrooms and the food/beverage industry.

Images for the Electric Roll Manipulator (ERM):

Powerful Roll Handling Device for Lifting and Turning Loads

Other Electrical Manipulators

Go to our Electrical Manipulators page for more information on this category of lifting tools.

Go to our main Tools page for an overview of the different categories of tools that we offer.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.