LnRiLWNvbnRhaW5lciAudGItY29udGFpbmVyLWlubmVye3dpZHRoOjEwMCU7bWFyZ2luOjAgYXV0b30gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWNvbnRhaW5lci50Yi1jb250YWluZXJbZGF0YS10b29sc2V0LWJsb2Nrcy1jb250YWluZXI9ImZmYTZmNDg5NWZkZjhhNGIzMmJmMjgyNjBiMDUyNzU1Il0geyBiYWNrZ3JvdW5kOiB1cmwoJ2h0dHBzOi8vMmxpZnQuZGsvd3AtY29udGVudC91cGxvYWRzLzI1MDNmNjQ0YTljMmRjM2RhM2YyNDNhYWJkYWM5MjIwNjk0ZDNmMDcuanBnJykgY2VudGVyIGNlbnRlciBuby1yZXBlYXQ7YmFja2dyb3VuZC1zaXplOiA3MDBweCBhdXRvO3BhZGRpbmc6IDI1cHg7bWluLWhlaWdodDogNTcwcHg7ZGlzcGxheTptcy1mbGV4Ym94ICFpbXBvcnRhbnQ7ZGlzcGxheTpmbGV4ICFpbXBvcnRhbnQ7LW1zLWZsZXgtZGlyZWN0aW9uOmNvbHVtbjtmbGV4LWRpcmVjdGlvbjpjb2x1bW47LW1zLWZsZXgtcGFjazpjZW50ZXI7anVzdGlmeS1jb250ZW50OmNlbnRlcjsgfSAudGItY29udGFpbmVyIC50Yi1jb250YWluZXItaW5uZXJ7d2lkdGg6MTAwJTttYXJnaW46MCBhdXRvfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtY29udGFpbmVyLnRiLWNvbnRhaW5lcltkYXRhLXRvb2xzZXQtYmxvY2tzLWNvbnRhaW5lcj0iNGQ5ZDg5ZDM1ZjAwYTMwYTRiYjhmYjdiZmRmZmI0MTAiXSB7IGJhY2tncm91bmQ6IHVybCgnaHR0cHM6Ly8ybGlmdC5kay93cC1jb250ZW50L3VwbG9hZHMvYnJlYWRjcnVtLWJnLnBuZycpIGNlbnRlciBjZW50ZXIgcmVwZWF0O3BhZGRpbmc6IDI1cHg7IH0gLnRiLWNvbnRhaW5lciAudGItY29udGFpbmVyLWlubmVye3dpZHRoOjEwMCU7bWFyZ2luOjAgYXV0b30gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWNvbnRhaW5lci50Yi1jb250YWluZXJbZGF0YS10b29sc2V0LWJsb2Nrcy1jb250YWluZXI9ImFjY2I5MjhmODg4Mzg0YjEwZjBkNWZlYTExYWJiOTcxIl0geyBwYWRkaW5nOiAwcHg7IH0gQG1lZGlhIG9ubHkgc2NyZWVuIGFuZCAobWF4LXdpZHRoOiA3ODFweCkgeyAudGItY29udGFpbmVyIC50Yi1jb250YWluZXItaW5uZXJ7d2lkdGg6MTAwJTttYXJnaW46MCBhdXRvfS50Yi1jb250YWluZXIgLnRiLWNvbnRhaW5lci1pbm5lcnt3aWR0aDoxMDAlO21hcmdpbjowIGF1dG99LnRiLWNvbnRhaW5lciAudGItY29udGFpbmVyLWlubmVye3dpZHRoOjEwMCU7bWFyZ2luOjAgYXV0b30gfSBAbWVkaWEgb25seSBzY3JlZW4gYW5kIChtYXgtd2lkdGg6IDU5OXB4KSB7IC50Yi1jb250YWluZXIgLnRiLWNvbnRhaW5lci1pbm5lcnt3aWR0aDoxMDAlO21hcmdpbjowIGF1dG99LnRiLWNvbnRhaW5lciAudGItY29udGFpbmVyLWlubmVye3dpZHRoOjEwMCU7bWFyZ2luOjAgYXV0b30udGItY29udGFpbmVyIC50Yi1jb250YWluZXItaW5uZXJ7d2lkdGg6MTAwJTttYXJnaW46MCBhdXRvfSB9IA==

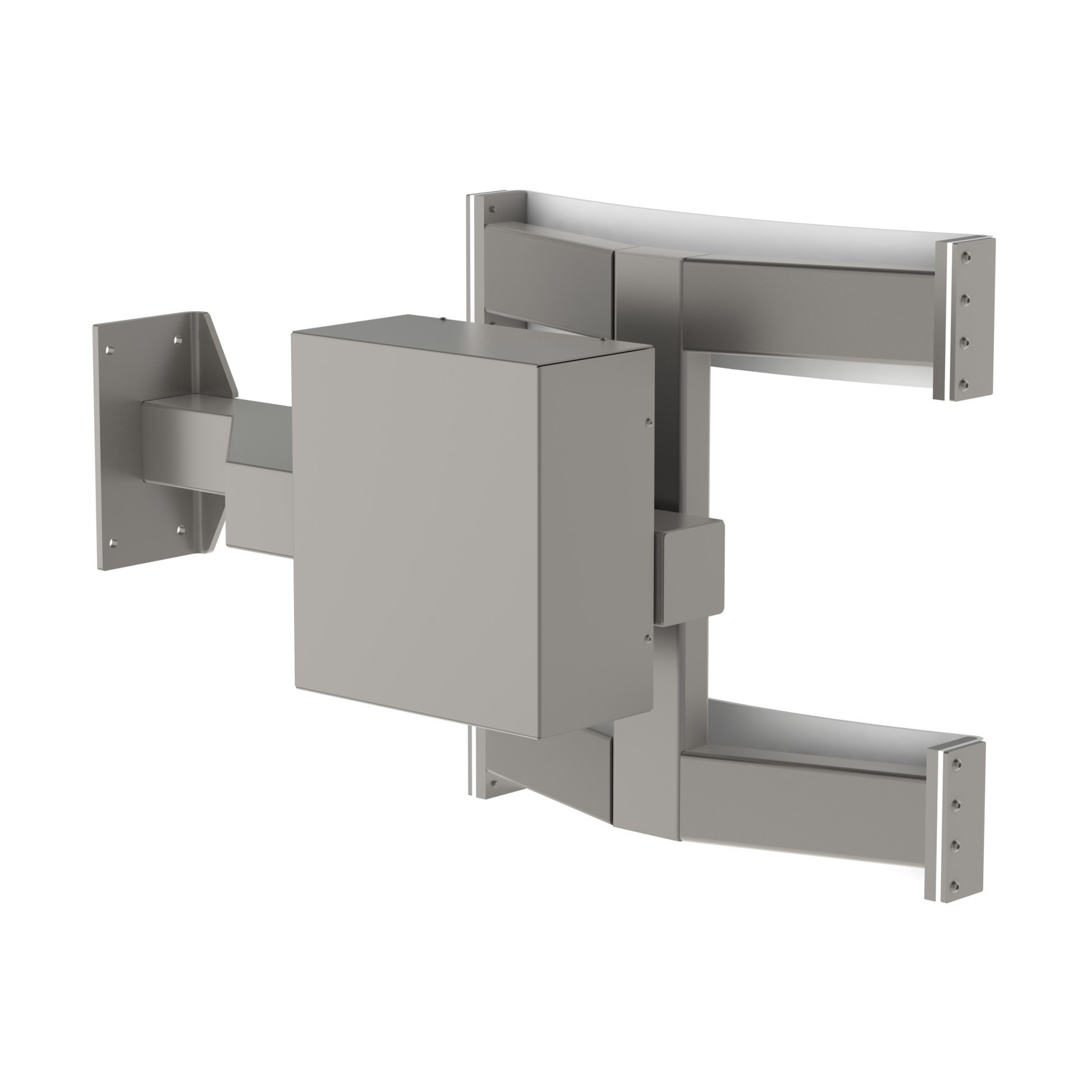

ERG – Electric Reel Gripper:

A Safe and Flexible Reel Handling Tool for Easy Positioning

Our special reel handling tool, the electric reel gripper (ERG), utilizes an electric actuator to grip reels on the outer diameter. The reel is held at three points with brackets that hook around the edge, keeping it firmly in place. For situations where reels with substantially different diameters need to be lifted, this reel handler tool can be equipped with sliders, allowing the brackets to be positioned according to the reel diameter.

Once the reel has been gripped, an additional electrical actuator allows the reel to be tipped 90 degrees, for positioning on a mandrel or an other holder.

The motion is easily controlled using the remote control on the lifter.

Features

- Can be adapted to fit multiple reel sizes.

- Fully electrically powered.

- Easily customizable: dimensions can be modified to customer specifications.

- Rugged construction for industrial use. With its all-stainless steel construction, the ERG is built to last and for use in demanding industrial environments.

- Available in hygienic design for use in cleanrooms and the food/beverage industry.

Images for the Electric Reel Gripper (ERG): Easy Reel Handling for Safe Docking

Other Electrical Manipulators

Go to our Electrical Manipulators page for more information on this category of lifting tools.

Go to our main Tools page for an overview of the different categories of tools that we offer.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.