SN-Line

SN-Line Vertical Lifts: Cleaning-Friendly Electric Lifters in Stainless Steel

The SN series represent our standard stainless steel vertical lifts for use in environments where keeping the lifter clean is very important.

All major exterior components, except wheels, are made of stainless steel (AISI 304) with a glass bead blasted surface.

The material handling lifts on this line are built with strong, durable and well-tested components which make these lifting machines an excellent choice for industries where working hours are long, perhaps constant, and the strain on the lifting equipment is considerable.

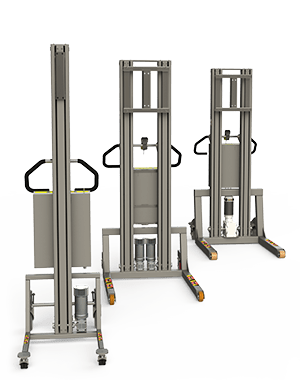

Our Versions of SN-Line Vertical Lifts

The SN-line lifting machines comes in three different versions reflecting three weight capacities for loads: the SN-150, SN-300 and SN-500. These three lifter variants are capable of lifting 150 kg, 300 kg and 500 kg (including the lifting tool), respectively.

These electric lifting devices will handle all of our different lifting tools – both simple, manual and electrical versions.

If you want more in-depth information on each of the lifters on the SN-Line, please follow the links below.

SN-150

SN-300

SN-500

An SN-Lift Is a Hygienic ‘Hybrid’ Ideal for Grade B Cleanrooms and Other Environments with Medium-High Cleanliness Requirements

The electric lifters on the SN-Line are ideal for controlled environments that have medium-high requirements for cleanliness, but do not follow the strictest of cleanroom protocols.

Thus they are ideal for usage in grade B cleanrooms which means that they are equivalent to ISO Class 5 at rest and ISO Class 7 in operation.

Our SN vertical lifts are typically used in demanding industry sectors such as pharma, food and beverage, cosmetics and semiconductors.

They are ideal for usage in laboratories or in storage areas where they transport loads from a grade B cleanroom to e.g. an airlock leading into a grade A cleanroom. Thus this lifter ‘hybrid’ often functions as a physical liaise between a highly controlled environment and a less controlled environment.

The loads typically consist of production equipment or various vessels containing materials and ingredients for the manufacturing process. Thus the SN lift is often used to lift and transport everything from drums, barrels, rolls, boxes, containers and various specialized equipment.

Since this lifting solution most often does not operate in the manufacturing and production environment itself, it does not need to be explicitly water proof (IP65) or made in 316L stainless steel which is what we build our lifters in when they need to be used in highly corrosive environments.

A Strong, Water Resistant and Cleaning-Friendly Lifter

Except for the wheels, the lifting equipment of the SN-Line is built in strong components made in AISI 304 austenitic stainless steel which means that is has excellent corrosion resistance.

Furthermore lifters in the SN series have an IP rating of 31. IP stands for ‘ingress protection’. IP designates how resistant the steel surface is against solids (dust and dirt) and water. Stainless steel with IP31 can withstand vertically dripping water.

‘Translated’ to real life usage, this means it has a medium level of water protection which enables the SN lifting machines to be surface-cleaned with a wet cloth. They are thus water resistant, but not fully waterproof.

Our Modular Approach Ensures Exceptional Flexibility

All our lifting aids – and thus those on the SN-Line, too – are built on a modular concept. This means that we can easily mix and match our lifters with our standard lifter tools which is beneficial for keeping the price at a reasonable level.

Furthermore the design is built to be easily adaptable to custom-built solutions meaning we can easily adjust the two main parameters related to the lifter:

– The lifter itself – height of the lifting columns, length of the legs etc.

– The lifting tools – size and dimensions

If your load has very special dimensions we can also custom build from scratch.

SN-Line Options for Special Work Situations and Environments

To optimize on work processes in terms of ensuring efficiency and seamlessness, we have designed a number of customised options that can be built into your chosen lifting equipment.

For vertical lifts on the SN-Line we can offer ATEX compliant lifters, docking systems, stainless steel for extremely corrosive environments (316L), ESD safe lifters, exchangeable batteries, a programmable position stop system and a rapid tool change adaptor.

ATEX

For use in environments with explosive atmospheres (EX-zone), we offer lifters that are compliant with the ATEX-directive.

Docking System

There are situations where it is critical that the lifter is positioned at a precise location. In cases like this, we offer a docking system that allows for quick and easy positioning of the lifter.

EN 1.4404 – AISI 316L

For use in extremely corrosive environments, we can deliver our stainless lifters in AISI 316L / EN 1.4404.

ESD – Electrostatic Discharge

For use in environments were the build-up of static electricity is prohibited, we offer lifters that are compliant with the electrostatic discharge standard.

Exchangeable Battery

The exchangeable battery system ensures that the lifter is always charged and ready to go.

PPS – Programmable Position Stop

The programmable position stop system (PPS) allows the user to pre-select 10 height positions, which can then easily be recalled allowing the lifter to stop precisely at the desired height.

RTC – Rapid Tool Change

The rapid tool change adaptor (RTC) allows the same lifter to use multiple lifting tools and makes exchanging these easy and time efficient.

Do Your Cleaning and Hygienic Requirements Exceed Those of the SN-Line?

If your work environment is subject to an even higher level of environmental control than that characteristic of grade B cleanrooms and / or the lifting machines need to be fully waterproof, we recommend taking a look at our SF-Line (for the food and beverage industry) or SP-Line (for the pharmaceutical industry).

The stainless steel vertical lifts in these series are built with an ingress protection of IP65 which means that they are dust tight and can resist flowing water – thus allowing for easy cleaning with a hose.

Our Other Lines of Vertical Lifts

C-Line

N-Line

SF-Line

SP-Line

Go to our Lifters page for a more detailed overview of our lifter lines.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.