SF-line

SF-Line Vertical Lift Options: Ideal for the Food and Beverage Industry

Our SF-line of lifters is specially tailored for the food and beverage industry with a strong focus on corrosion resistant materials and hygienic design.

The vertical lift solutions of the SF-line is compatible with all of our lifting tools, simple, manual as well as the electrical versions.

Custom handling solutions and a wide range of options are also available to suit almost any need.

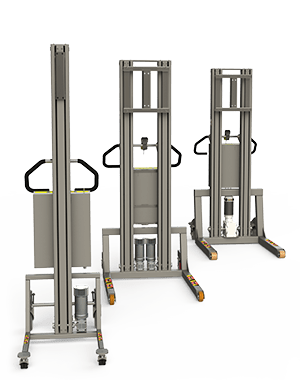

Our Versions of SF-Line Vertical Lift Equipment

The SF-line lifting machinery comes in three different versions, the SF-150, SF-300 and SF-500. These are capable of lifting 150 kg, 300 kg and 500 kg (including the lifting tool), respectively.

Please follow the links below for more detailed information on each of the versions of the SF-line.

SF-150

SF-300

SF-500

Our Hygienic Material Handling Equipment Is a Good Match for Any Food Sector and Food Segment

Here at 2Lift we have been steady suppliers of electric lifters for the food and beverage industry for many years. We believe we have encountered most of the hygienic challenges in this industry and found good, strong and efficient materials and designs to help to solve them. We have experience serving all sectors including the demanding sectors of production, processing (manufacturing) and packaging.

Our minilifts are optimally designed to be used in any work process in any segment, environment and situation e.g. aiding in the process of:

– Beverage manufacturing and distribution

– Dairy production, packaging and transport

– Grain milling, malting, mixing and packaging

– Meat processing and packaging

– Sugar refining and manufacturing

– Fruit / vegetable transport, production and packaging

Our Lifting Machinery Will Handle Both Standard and Specially Dimensioned Loads

Most production and manufacturing sites such as dairies, kitchens, wineries, mills, bottling, bakeries, breweries and the like need help handling heavy loads such as raw materials, containers, production equipment, packaging materials, and of course the final products.

Our modularly built electric lifting devices can be equipped with both standard and custom designed lifting tools that can lift, turn, tip, pour, and empty both:

– Standard loads such as drums, barrels, rolls with foil and paper, reels, boxes, crates, pallets, dollies bins, canisters etc.

as well as …

– Unique loads such as special dimensioned containers, carboys, bowls, vessels, lids, trays, moulds, machine parts, mixing and blending equipment, filters and centrifuges, various types of extruders etc.

The “Must” in Food Manufacturing:

Meeting the High Demands of Hygiene to Ensure Product Purity

To ensure product safety for consumers a production site needs to follow international and national sector/segment regulations. We are well versed in matching and following relevant food industry standards such as GMP (Good Manufacturing Practices), ISO 22000, The Safe Quality Food (SQF) Program as well as various standards for equipment in direct contact with food such as the AISI standards (from the American Iron and Steel Institute).

Very High Corrosion Resistance in Our Stainless Steel Components

When using equipment in food and beverage production areas, it is vital that not only is the material used in the lifting equipment strong and durable it also needs to be non-toxic, non-corrosive and non-absorbent.

For this very reason all metal parts on a vertical lift from the SF line are made in austenitic stainless steel, which makes the steel very strong and durable. The high chromium content in the metal provides a protective ‘self-healing’ film on the surface of the steel. This means that regardless of potential physical harm done to film, it will still protect the metal, as it regenerated when in contact with oxygen. This is a very powerful feature.

At 2Lift we can offer two types of stainless steel suitable for food and beverage processing environments. AISI 304 is our standard stainless steel alloy in this series well suited for most food environments. It has an excellent corrosion resistance and can handle caustic chemicals and very high temperatures.

However, for particularly high corrosive environments we recommend using components in AISI 316L. This stainless steel variant have all the benefits of AISI 304, and then some. The higher content of molybdenum in 316L provides it with an even higher melting point and an even higher corrosion-resistance. This makes 316L the better choice in highly saline or acidic production environments.

Intelligent Design and Good Craftsmanship Ensures Impeccable Hygiene Features

All our lifting solutions in this series are designed in a way that make them safe as well as easy to clean.

First of all our lifters have an IP rating of 65. IP stands for “ingress protection”. This means that all electrical enclosures are safe from the entering of foreign particles such as dust and water. How much they are protected from such particles is defined by the number. At 2Lift we use a protection rate of 65 which means that it is totally dust tight and can handle low-pressure jets of water. In other words it is well suited for a good hosing down.

In fact, and perhaps surprisingly, our lifters are particularly fond of a good and thorough cleaning. Not only does cleaning make the lifters even more corrosive resistant (by removing dirt, bacteria etc.), you can also access and clean all parts of the lifter, even the internal lifting mechanics.

One of the many benefits of stainless steel is that is has a very smooth surface. In technical terms a smooth surface will have a low surface roughness (Ra). A low surface roughness is important if you want to prevent dirt, dust, bacteria, food particles etc. from taking up residence in microscopic surface cracks.

Also to further safeguard a sanitary surface design, our highly skilled welders ensure a smoothe, crevice-free surface at the potentially vulnerable joints where components are welded together.

SF-Line Options for Special Food Environments and Situations

To enhance safety and seamlessness in work processes we have designed a number of customised options that can be added to your lifting solution. In the case of our SF series all our special options are available except for alternative RAL colour. This feature is only available for our non-stainless steel lifters (C-Line and N-Line).

Otherwise can offer ATEX compliant lifters, docking systems, stainless steel for extremely corrosive environments (as already mentioned), ESD safe lifters, exchangeable batteries, a programmable position stop system and a rapid tool change adaptor.

ATEX

For use in environments with explosive atmospheres (EX-zone), we offer lifters that are compliant with the ATEX-directive.

Docking System

There are situations where it is critical that the lifter is positioned at a precise location. In cases like this, we offer a docking system that allows for quick and easy positioning of the lifter.

EN 1.4404 – AISI 316L

For use in extremely corrosive environments, we can deliver our stainless lifters in AISI 316L / EN 1.4404.

ESD – Electrostatic Discharge

For use in environments were the build-up of static electricity is prohibited, we offer lifters that are compliant with the electrostatic discharge standard.

Exchangeable Battery

The exchangeable battery system ensures that the lifter is always charged and ready to go.

PPS – Programmable Position Stop

The programmable position stop system (PPS) allows the user to pre-select 10 height positions, which can then easily be recalled allowing the lifter to stop precisely at the desired height.

RTC – Rapid Tool Change

The rapid tool change adaptor (RTC) allows the same lifter to use multiple lifting tools and makes exchanging these easy and time efficient.

Our Other Lines of Vertical Lift Solutions

C-Line

N-Line

SN-Line

SP-Line

Go to our Lifters page for a more detailed overview of our lifter lines.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.