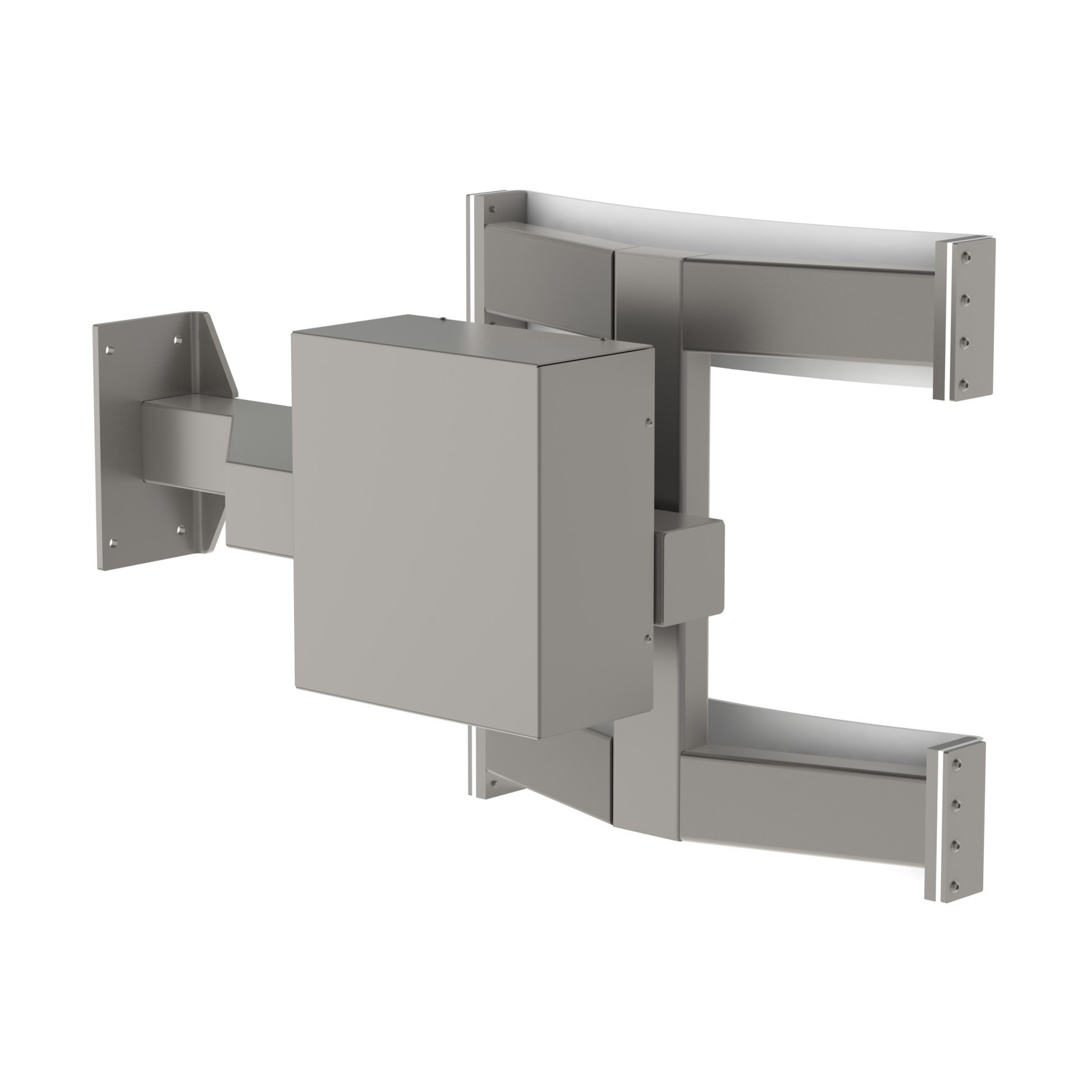

ERU – Electric Rotation Unit

ERU – Electric Rotation Unit:

Precise Rotation of Heavy Loads on a Roll Handler or Drum Lifting Device

Typically mounted on a drum lifting device or roll handler, this fully electrical version of our rotation unit allows the user to rotate a load simply by pushing a button on the lifter’s remote control. Internally, a motor worm gear provides the rotational motion and ensures that the load stays in place, since the gear is self-locking.

The ERU is perfect for heavy, off-centre loads, which need to be manipulated in a precise and controlled manner.

The ERU is supplied with an encoder that keeps track of its position. As such, the unit will stop automatically in the central position and optionally in two preprogrammed positions in both clockwise and counter clockwise direction.

Features

- Rotation up to 180 degrees in both clockwise and anti-clockwise position.

- Automatic stop in central position.

- Fully electrically powered

- Rugged construction for industrial use. With its all-stainless steel construction, the ERU is built to last and for use in demanding industrial environments.

- Available in hygienic design for use in cleanrooms and the food/beverage industry.

Images for the Electric Rotation Unit (ERU):

Easy and Controlled Rotation Tool for a Drum Lifting Device or Roll Handler

Other Electrical Manipulators

Go to our Electrical Manipulators page for more information on this category of lifting tools.

Go to our main Tools page for an overview of the different categories of tools that we offer.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.