N-Line

N-Line Lifting Machinery: A Solid Choice for Most Environments

Our standard lifting machinery for use in most environments. All major components are made of steel (powder coated), making these industrial lifters strong and durable.

Based on durable and tested components, this line of material handling equipment is built for industry with prolonged and hard use in mind.

Our Versions of N-Line Lifting Machinery

The N-line lifting machines come in three different versions, the N-150, N-300 and N-500. These are capable of lifting 150 kg, 300 kg and 500 kg (including the lifting tool), respectively. These lifters will handle all of our different lifting tools – non-manipulators as well as manipulators (manual and electrical versions).

Please follow the links below for more detailed information on each of the versions on the N-line.

N-150

The lightest lifter in the N-line. Easy to manoeuvre, highly adaptable and capable of lifting up to 150 kg (including the mounted lifting tool).

N-300

The N-300 is the medium sized lifter in the N-line. This lifter is capable of lifting up to 300 kg (including the mounted lifting tool) and able to utilise all of our lifting tools, both manual and electric.

N-500

The N-500 is the largest lifter in the N-line. Capable of lifting up to 500 kg (including the mounted lifting tool) and highly adaptable, making it a perfect choice for heavy loads.

Need to Both Lift and Do More Complex Manipulation with the Loads?

The N-Line Lifting Equipment Is a Solid and Flexible Choice for Most Tasks

The lifting aids on the N-Line are built on a modular concept thus designed to fit all our standard lifting tools, including our whole selection of electrical lifting tools, thus adding more options for complex load manipulation such as e.g. turning and tipping.

The N-Line lifting machine is also easily adaptable to custom-built solutions.

Very Flexible Lifting Machinery for Lifting and Manipulating Everything from Rolls and Drums to Boxes and Pallets

Again, thanks to our modular design these lifting solutions are able to handle a very broad variety of loads:

– For roll handling (paper, foil, film, labels etc.) we have several options for both internal roll handling (i.e. in the core) and gentle external handling.

– For handling drums and other cylindrical or round vessels (barrels, containers etc.) we have many types of scissor clamps, linear clamps and platforms.

– For handling boxes of various sizes and dimensions, we can offer different types of forks, scissor clamps and platforms.

– For lifting pallets, our fork, which can be easily modified, is a good and solid choice.

Once again, if a load doesn’t fit our standard tools, we can easily adapt the tool to match the load as well as the specific environmental needs requiring taking into consideration special space requirements and spatial restrictions.

The N-Line Is a Good, Solid Fit for Most Industries and Environments

Being both strong, durable and versatile the N series is a good solid choice for most industries. Our N-Line lifter can be found all over the world in various manufacturing and production environments such as those for e.g. for electric motors, fuel cells, machine parts, money machines, batteries, ceramic materials, semi-conductors, electronics, contact lenses and many more.

The N-Line is also a very suitable choice for the general storage and packaging industry.

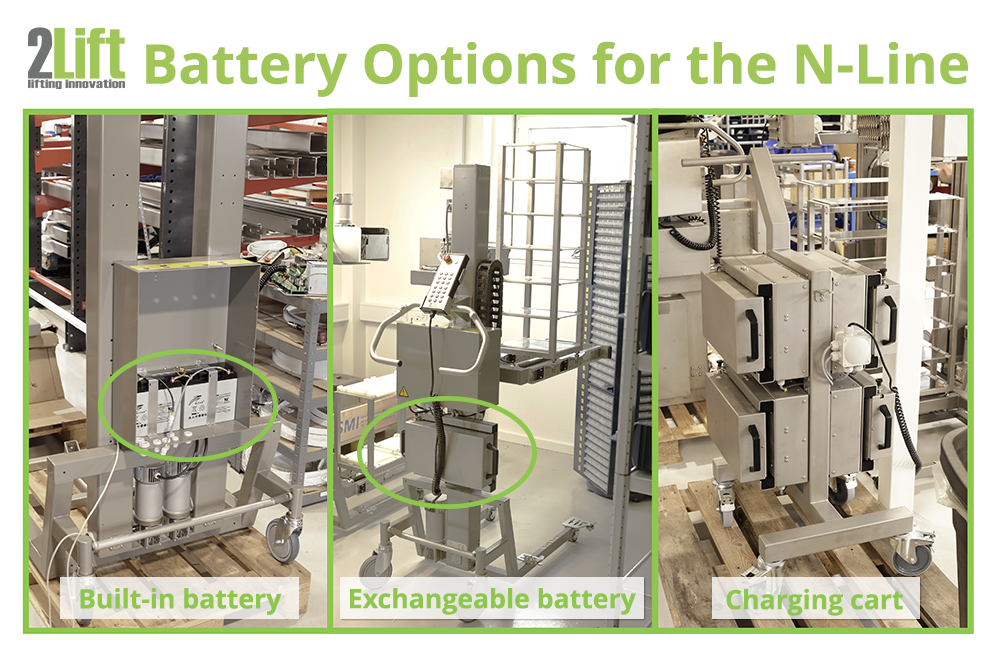

The N-Line Comes with a Powerful Battery Capacity and Exchangeable Battery Option

One of the strongest features on the N-Line is its battery.

The N-line material handling equipment comes with a very powerful built-in battery.

If your work circumstances require an even larger battery capacity than what the built-in battery has to offer, you have the option of choosing our lifter with an exchangeable battery.

This additional battery option is ideal in situations when the lifting machinery will be working continuously throughout the day, shift after shift.

N-Line Options for Special Work Situations and Environments

To ensure as efficient a work flow as possible, we have designed a line of options that can be added to your N-Line lifting apparatus. For this line specifically we offer among other things a docking system, a rapid tool change adaptor and a programmable position stop.

The standard colour on the N-Line is that of RAL 9007 which is achieved by powder coating; other RAL colours are available on request.

Furthermore we can, as already mentioned, offer the option of an exchangeable battery.

Docking System

There are situations where it is critical that the lifter is positioned at a precise location. In cases like this, we offer a docking system that allows for quick and easy positioning of the lifter.

RTC – Rapid Tool Change

The rapid tool change adaptor (RTC) allows the same lifter to use multiple lifting tools and makes exchanging these easy and time efficient.

PPS – Programmable Position Stop

The programmable position stop system (PPS) allows the user to pre-select 10 height positions, which can then easily be recalled allowing the lifter to stop precisely at the desired height.

Alternative RAL Colour

Our non-stainless lifters (N line) can be supplied in alternative RAL colors in addition to the standard colour.

Exchangeable Battery

The exchangeable battery system ensures that the lifter is always charged and ready to go.

Do Your Cleaning Requirements Exceed Those of the N-Line?

If your environment is somewhat more controlled in the sense that it needs to be kept clean but it is not imperative that it is at a cleanroom level, we recommend the lifters in our SN-Line. These lifters are built in stainless steel plus they have all the benefits of this line, thus being robust and flexible.

If your hygienic demands are very high, e.g. you need to be able to hose down the lifter or it needs to function in a sterile environment, we recommend taking a look at our SF-Line for the food and beverage industry or our SP-Line for the pharma industry.

Our Other Lines of Lifting Machinery

C-Line

C-Line material handling products are lightweight and highly manoeuvrable. C-Line lifters are built in steel and the lifter tools are non-electric. Electric lifters from this line can lift up to 150 kg loads and battery capacity is lower than what is the case on the other lines. These are our most economically priced lifters.

SN-Line

The SN-line features our basic stainless steel lifter. The waterproof grading is IP31, which makes it suitable for surface cleaning with a wet cloth, but not a rinsing down with a hose. Not all components are of stainless steel – this goes for components inside the column and on the wheels. Lifting equipment from this line can lift loads of either 150 kg, 300 kg or 500 kg.

SF-Line

The SF-range of lifters are specifically tailored to the high demands pertaining to the food and beverage industry. These stainless steel lifters are fully waterproof with an of IP65 which means they are built to withstand a good hosing down with water. Components such as lifter column and motor department are not built to keep out particles, which means it not built for cleanroom use. These lifters come in a 150 kg, 300 kg and 500 kg variant.

SP-Line

Stainless steel lifters tailored for the pharmaceutical and biotech industry with focus on hygienic design. Rated IP65 and with a total lifting capacity between 150 and 500 kg.

Go to our Lifters page for a more detailed overview of our lifter lines.

Go to our Products page to find out how our products may help you in your line of industry and your work situation.

Go to our Homepage.